Fine Grinding Products

We are a recognized leader in providing world-class fine grinding products including superabrasive wheels, dressing stones, and parts carriers. Our wheels incorporate the finest quality and extremely close graded diamond, black CBN and amber CBN in conjunction with our specially formulated vitrified and resin bonds. Dressing stones are available to suit all fine grinding wheel formulations and sizes.

Fine Grinding Wheels / Superabrasive wheels

- Faster Material Removal Rates

- Finer Finishes

- Better Flatness Control

- More Consistent Process Control

- Very Competitive Pricing

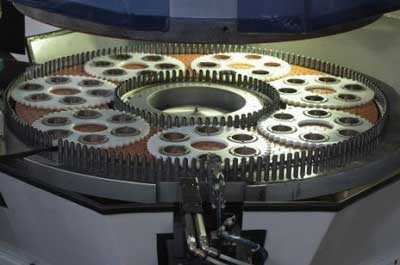

The fine grinding process produces flat lapping quality on a variety of materials without the expense and “mess” associated with lapping. Fine grinding wheels produce material removal rates are up to 20 times faster than lapping. Our special vitrified and resin bonds combined with our use of the highest quality most closely graded super abrasive powders means consistent quality for all parts ground. Vitrified wheels are supplied with configurations comprised of round, square or hexagonal pellets applied to steel backup wheels.

The fine grinding process produces flat lapping quality on a variety of materials without the expense and “mess” associated with lapping. Fine grinding wheels produce material removal rates are up to 20 times faster than lapping. Our special vitrified and resin bonds combined with our use of the highest quality most closely graded super abrasive powders means consistent quality for all parts ground. Vitrified wheels are supplied with configurations comprised of round, square or hexagonal pellets applied to steel backup wheels.

Pellet type wheels are available with spaces (grooves) between the pellets or with the inter-pellet spaces filled to provide a smooth surface. Segmented wheels which appear as a solid grinding surface are also available. Grinding surface pattern, abrasive particle size, bond and thickness of grinding media are all customized for your specific application. Vitrified bonds are the longest lasting and easiest to control for flatness. Our resin bond wheels are provided with a solid segmented grinding surface. This surface can be either serrated or plain depending on the application. Resin wheels are suited for applications where minimal material removal and fine surface finish are required. A variety of wheel diameters are available to suit your single side or double side fine grinding needs. Our fine grinding technicians are available to determine wheel specifications best suited for your specific application(s).

Parts Carriers

Work holder Discs and Pads – Single Sided Machines

Work holder Discs are used to separate fragile workpieces during lapping and polishing operations to prevent damage. They are also used when work pieces do not lend themselves to batch loading. Pads are available in sponge rubber or felt material and are used to compensate for minimal height differential in the parts being lapped.

Work holder Discs are used to separate fragile workpieces during lapping and polishing operations to prevent damage. They are also used when work pieces do not lend themselves to batch loading. Pads are available in sponge rubber or felt material and are used to compensate for minimal height differential in the parts being lapped.

Work Piece Carriers for Double Sided Batch Processig Machines

We offer work piece carriers for virtually any double sided machine currently on the market. Stock materials include spring steel (strongest, most durable; for thin, precision components), steel with molded plastic inserts (for use in lapping and polishing silicon wafers and other sensitive electronic materials), G-10 (fiberglass reinforced, non corroding and non-water absorbing - ideal for thicker parts), PVC (for use with relatively thick parts), lexan (for scratch-free fine polishing applications), vinyl (most economical for short runs), and phenolic (resin-laminated cloth, for use with oil-based slurries). Workholes can be custom cut to suit any part geometry.