Work Holder Discs / Parts Carriers

A workholder disc is a device used to orient and space components within a conditioning ring. It prevents component contact with the conditioning ring as well as other components. A workholder takes the form of a thin disc of phenolic laminated plastic with its diameter measuring 1/16” smaller than the inside diameter of the conditioning ring. Phenolic laminated plastic is used because it is relatively inexpensive, possesses high rigidity strength to maintain flatness, doesn’t absorb liquid and is easily machined. Workholders are available for all single side models and in a variety of standard thicknesses from 1/32” to 1/2”.

Openings matching the component configuration are machined into the workholder to contain the parts. It is important to have clearance (approximately 1/32”) between the workholder and the components to avoid a binding condition. The workholder must never bind to the conditioning ring and components must never bind to the workholder. Components must always be allowed to self align the surface requiring lapping to the lap plate surface. The workholder must always be thinner than the finished thickness of the components when pressure plates are to be used or pressure will be applied to the workholder instead of the components.

The proper layout design for machining component openings in a workholder is always arranging the openings in concentric rings and spacing them as far towards the outside diameter of the workholder as possible. The openings should always be oriented so the longest axis of the component is aligned with the radius of the concentric ring of openings. This will provide for the most consistent stock removal rate possible.

Workholders are used when components cannot be batch loaded into the conditioning ring. This may be due to unusual component configurations, fragile materials, when using transposition techniques and when less than the maximum load of components is available for processing.

Lapmaster provides a set of 1/8” thick workholders with all single side machines up to the Model 36, 1/4” thick with the Models 48 and 56; and 1/2” thick with the Models 72 and 84.

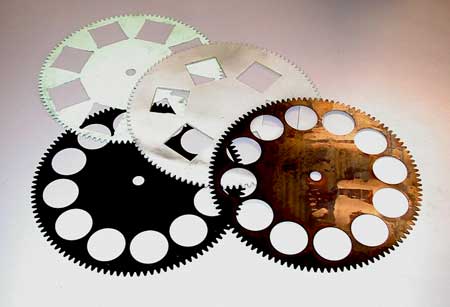

Work-carriers

Work-carriers are precision stamped or machined tooling that have gear teeth on their outside diameters. They can be fabricated from many materials such as fiberglass, plastic of many types and several types of metal. The work-carrier must precisely fit the gear pitch of the machine inner and outer drive gears as well as the components. Work-carriers are expensive due to the required precision and material they are fabricated from. Double-side machines consume work-carriers at a rapid pace because it is difficult or impossible to use spacer pads.

Work-carriers are precision stamped or machined tooling that have gear teeth on their outside diameters. They can be fabricated from many materials such as fiberglass, plastic of many types and several types of metal. The work-carrier must precisely fit the gear pitch of the machine inner and outer drive gears as well as the components. Work-carriers are expensive due to the required precision and material they are fabricated from. Double-side machines consume work-carriers at a rapid pace because it is difficult or impossible to use spacer pads.